UKNNL offers an internationally recognised capability in nuclear graphite technology that has evolved over fifty years: our experience and expertise traces back through predecessor organisations. We have been been the principal provider of graphite measurements and characterisation to the operators of the UK’s commercial nuclear power plants, a service that is key to the continued operation of such reactors.

This service consists of all physical, chemical and mechanical property measurements on graphite samples, taken from each reactor core every two to three years. The post-irradiation examination (PIE) data are essential in the support of the safe and continuous operation of the reactor cores as they provide confidence in the current understanding of core graphite behaviour and the suitability of the models used to predict changes in graphite properties due to exposure in the reactor environment.

Our full suite of irradiated graphite characterisation services includes:

- Bulk density by three different methods

- Helium volume

- Gas diffusivity

- Gas permeability

- Dynamic Young’s modulus

- Compressive, flexural and tensile strength,

- Coefficient of thermal expansion (CTE)

- Thermal diffusivity

- Electrical resistivity

- Rate of release of stored (Wigner) energy and total stored (Wigner) energy

- Specific heat capacity

- Oxidation behaviour by thermal gravimetric analysis

- Optical microscopy (bright field, fluorescent and polarised light)

- Scanning Electron Microscopy (SEM)

- Transmission Electron Microscopy (TEM)

- Laser Raman spectroscopy

- X-Ray Diffraction (XRD)

- X-Ray Microtomography

The specialist expertise gained from designing and testing the limitations of these measurement techniques is fed back to the wider scientific community through participation in the ASTM subcommittee D02 for Manufactured Carbons and Graphites. In order to cross-compare the accuracy and reproducibility of the test methods used on the reactor samples, UKNNL has participated in many inter-laboratory studies in support of new standards and has led the production of the following standards:

- ASTM D7775 Standard Guide for Measurements on Small Graphite Specimens

- ASTM D7972 Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

- ASTM D8075 Standard Guide for Categorization of Microstructural and Microtextural Features Observed in Optical Micrographs of Graphite

In collaboration with Idaho National Lab and Oak Ridge National Lab, UKNNL led the ASTM Selected Technical Papers publication on ‘Graphite Testing for Nuclear Applications: The Significance of Test Specimen Volume and Geometry and the Statistical Significance of Test Specimen Population’ (ASTM STP 1578). (Figure 1)

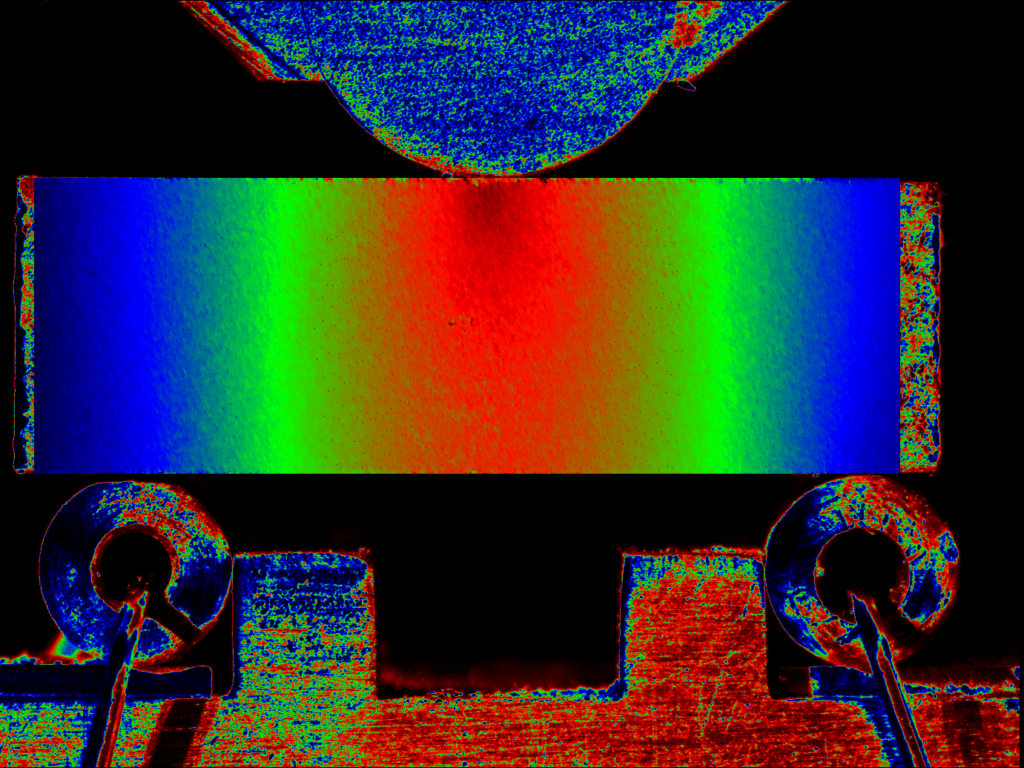

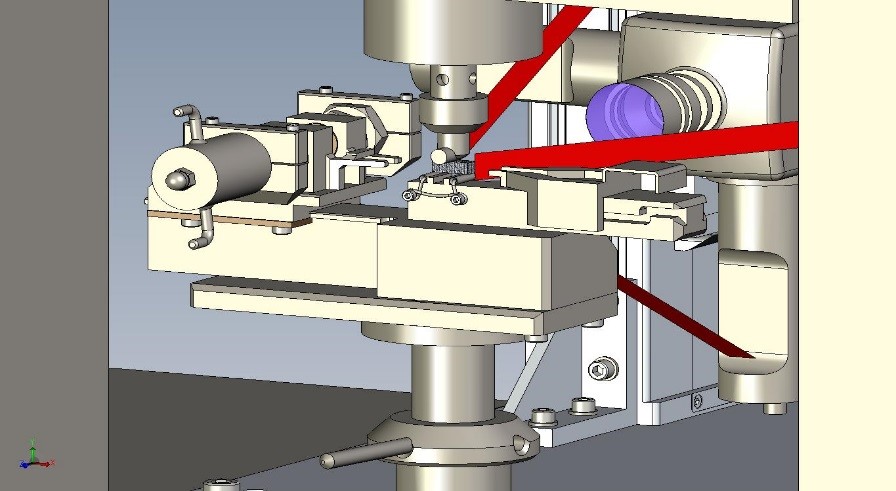

In addition, UKNNL has worked with EDF to develop and prove new state-of-the-art techniques that either validate existing measurement techniques or provide additional materials property insights that could be used to enhance understanding of the behaviour and properties of graphite in nuclear reactor cores. An example of the former is the development of ESPI (Electronic Speckle Pattern Interferometry) for the measurement of two mechanical properties of graphite – static Young’s modulus and Poisson’s ratio (Figure 2).

This technique has given very good agreement with the PIE measurements of dynamic Young’s modulus using the ultrasonic time-of-flight technique. Similarly, ESPI has been developed to measure the coefficient of thermal expansion and has been shown to be in good agreement with the corresponding PIE measurements by the established technique of dilatometry.

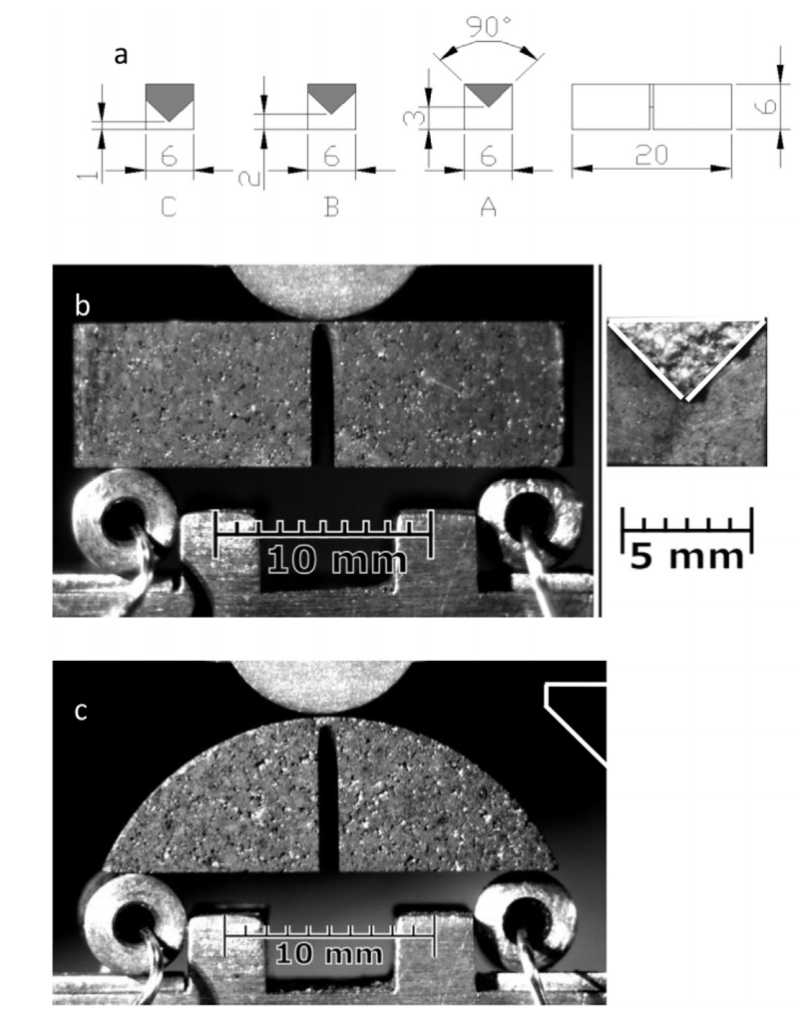

More recently, in collaboration with EDF and The University of Manchester, UKNNL has completed an Innovate-UK project on ‘The Influence of Creep and Geometry on the Strength of Irradiated Graphite Components’. Under this project, EDF and UKNNL developed a new technique for measuring the work of fracture of small irradiated graphite samples – a key indicator of the ability of the material to resist the growth of cracks.

After proving on unirradiated graphite and two other materials (macor and PC45), the method was successfully used on reactor samples confirming our understanding of the changes in graphite fracture properties with irradiation. The method was also successful on the ‘wing’ specimens (Figure 3c) produced from the samples of graphite from reactor cores, giving the opportunity to obtain more information on the same material and correlate with other properties, such as flexural strength and elastic modulus, measured on the same samples.

This work has been published in the Journal of Nuclear Materials (Measuring the fracture properties of irradiated reactor core graphite, A Tzelepi, Paul Ramsay, Alan G. Steer, John Dinsdale-Potter, JNM 509 (2018) 667-678) and the technique has been included as an ASTM Standard Guide:

ASTM D8255 Standard Guide for Work of Fracture Measurements on Small Nuclear Graphite Specimens