Tuesday 23 April 2024

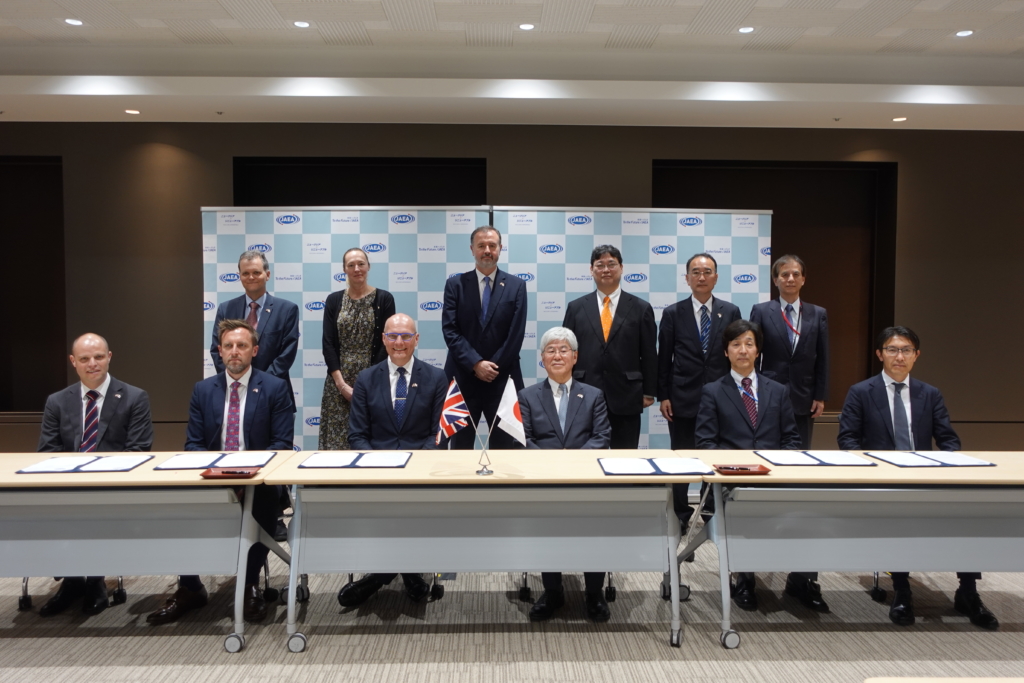

NNL and the Japan Atomic Energy Agency (JAEA) strengthen the relationship between the two laboratories in a collaboration agreement for advanced nuclear fuel.

The UK’s national laboratory for nuclear fission and its counterpart in Japan have signed an agreement as part of the Department for Energy Security and Net Zero Step 1 Coated Particle Fuel Programme in the UK.

UK Government funding has already enabled NNL to produce coated particle fuel (CPF) at scale in its laboratory in Preston, England, and this will be further strengthened by the unique and unrivalled expertise from colleagues from Japan, where CPF fuel has historically been manufactured for use in the High Temperature Engineering Test Reactor (HTTR). CPF is an advanced fuel used in high temperature gas-cooled reactors. It is extremely robust as each kernel of uranium is coated in four protective layers.

This agreement builds on the cooperation signed by NNL and JAEA in London in September 2023, as part of the UK Government’s programme to support the development of high temperature gas-cooled reactors (HTGR) for deployment in the UK.

Emma Vernon, NNL’s Vice President for Government and New Build said:

“This agreement will further strengthen the relationship between the two laboratories and demonstrates the importance of international collaboration to innovate together to progress advanced nuclear technologies. The collaboration will bring together the skills that JAEA have developed in coated particle fuel over decades, along with the world class facilities that we have developed here in the UK to deliver sovereign fuel. This is critical technology to enable the UK to achieve net zero.”

Following the signing ceremony, the delegation from NNL will visit the HTTR at Oarai, Japan. Last month, a delegation from NNL was invited to be present at the demonstration of the inherent safety features of the HTTR. This reactor is designed to cooldown through natural processes even when the primary coolant flow is paused, and the control rods are not inserted.

“The JAEA team ran the reactor at 100% power (30MW) and an outlet temperature of 850 ˚C and then stopped the forced helium gas coolant. As expected, after a short time, the reactor automatically decreased power and remained stable. In addition, the fuel, where the uranium kernel is encased in four layers comprising silicon carbide and carbon retained its integrity. It was an historic moment for the whole industry, and I was very excited to be a part of it.”

HTGR technology has been identified by the UK and Japanese Governments as one of the most promising technologies to have a significant impact on net zero due to its proven ability to provide heat to industry without the need to burn fossil fuels.